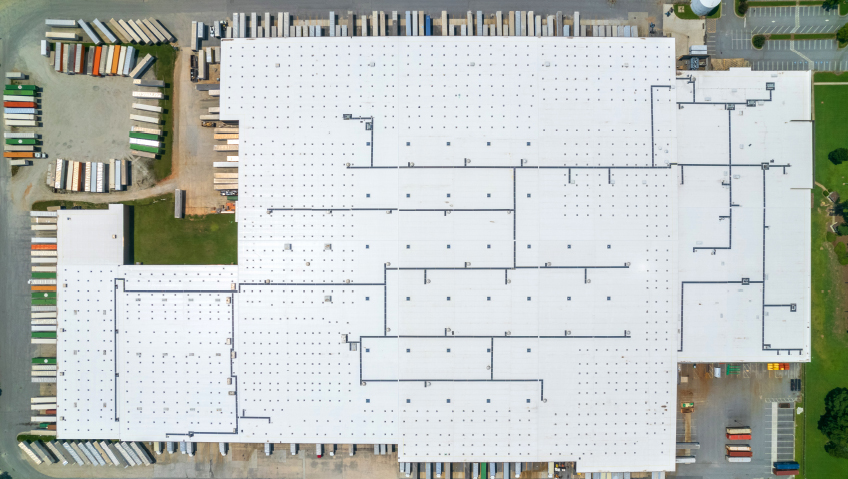

Tearing off and replacing roofs, often measuring thousands of square feet, on warehouses, schools, hospitals, condos, and massive commercial and industrial buildings is a big, messy, and expensive process. Insulated Roofing Contractors (IRC) offers building owners the smart, non-destructive solution: durable, cost-effective, and long-lasting sprayed polyurethane foam (SPF), professionally applied to existing roofs, making them weather-resistant, insulated, and watertight.

For the past 50 years, this Indiana-based company has held the distinction of being America’s largest spray foam contractor. SPF roofs as applied by Insulated Roofing Contractors—a seamless system that has an impressive 35-year average lifespan—have many benefits over other products like modified bitumen, Thermoplastic Polyolefin (TPO), urethane, acrylic, and other applied-liquid roofing.

In addition to SPF roofing, the company has also incorporated many other roofing solutions including single ply, and has been recognized with awards in that area of roof servicing as well.

Family values

Since opening its doors in 1974, Insulated Roofing Contractors has completed between 10,000 and 12,000 jobs, installing at least 150 million square feet of insulated roof. Working across all 50 states and taking on some jobs in Canada, Insulated Roofing has consistently been the #1 choice of building owners, and for good reason.

“We’ve always done commercial roofing, and never tapped into the residential market,” says Marketing Director Justin Baird of the company started by his grandfather, Melvin Stumler, Melvin’s brother, and another partner in 1974. Over time, some investors sold their shares in the business while other family members joined the company, which remains proudly family-owned a half-century later.

“My grandfather was presented with this business opportunity, saw that everybody needed a roof, and the rest is history,” says Baird, who started working summers at the business.

Starting out with just a single truck and trailer and a lot of polyurethane foam, the business today employs between 130 and 140 field and office employees, depending on the season. While displaying impressive growth, IRC has upheld its reputation for quality, customer service, and adherence to family values.

“Loyalty goes a very long way,” says Baird of the company’s high staff retention rate. “We treat everybody like family here at Insulated Roofing. I have actual family members who work for me, but I consider every single person in the office and in the field our family as well. I feel like everybody here at Insulated has a sense of belonging. They feel appreciated. We always look out for them if they need anything, and we’re always there for them—and that’s outside of work as well.”

Benefits of SPF

For existing and new roofs alike, there are many advantages to sprayed polyurethane foam.

Once the original roof has been inspected and any necessary repairs made, the team at IRC applies SPF directly on top of the roof system. This means heavy materials don’t have to be hoisted onto rooftops. Since the application is made in a single, roof-applied monolithic sheet without seams or fasteners, the chances of an SPF roof leaking are extremely slight, and thermal bridging is eliminated. Able to withstand brutal weather like wind uplift and hail, SPF roofs perform well year after year while also providing some noise cancellation.

Quicker to install than traditional roofing, SPF conforms to irregular shapes and expands to fill cracks, ensuring a weatherproof seal. Serving as a moisture and air barrier, SPF also has the highest R-value on the market, making it a great insulator and keeping out extreme temperatures.

“Although other systems might be cheaper upfront, in the back end, SPF will actually save you money, because it decreases all your energy expenses,” says Baird. “So it keeps the heat in when it’s cold outside and keeps the cool in when it’s warm outside.”

Customers can also purchase IRC’s annual maintenance agreement. Trained staff come out twice a year, in the fall and spring, when they clean and inspect the roof to ensure its peak condition. Clients can also take advantage of the company’s 10, 15, or 20-year warranties.

“In the unlikely event of anything happening to your roof, we come out, assess the damage, and fix the problem,” says Baird. As long as the sprayed polyurethane foam is maintained, the application will last for decades.

And one of the greatest perks of an SPF roof is that once it goes out of warranty, a new silicone coating applied on top puts the roof back under warranty. “It saves you money that way as well because you don’t have to replace your entire roof with a new roofing system. We just go through and spray on the coating.”

For the initial process, team members assess the existing roof. This includes power washing the roof and laying and securing insulation board. A minimum of one and a half inches of SPF is applied and sloped toward drains, creating a watertight barrier. The coating is then sprayed with granules to offer traction and safety.

Projects big and small

As experts in sprayed polyurethane foam, Insulated Roofing Contractors can take on jobs of all sizes. While most projects are straightforward, others are massive and present unique challenges, as happened in 2005 when Hurricane Katrina struck the United States, tearing off roofs, knocking down entire buildings, and leaving many without shelter.

One of the biggest casualties, in roofing terms, of the hurricane’s brutality was the ethylene propylene diene terpolymer (EPDM) rubber roof of the Louisiana Superdome, one of America’s biggest stadiums. On installation, it had been confidently asserted that the roof would withstand winds of up to 200 mph (322 km/h).

This turned out to be a rather optimistic estimate and Hurricane Katrina, with windspeeds of 74 to 95 mph (119 to 153 km/h), made short work of the stadium covering. With the National Football League fall schedule fast approaching, there was an urgent need for repair.

Says IRC: “At the end of the day, after researching all available roof systems on the market, the architects, engineers, and consultants for the state recommended the installation of a spray polyurethane foam roof.” Bids were put out and, while a different roofing contractor was actually awarded the project, the accelerated timeline and difficulty of the scope of work led that contractor to subcontract IRC to complete 50 percent of the work in order to meet deadlines.

The company deployed crews, many of whom stayed in rented trailers. With 20 to 30 team members working day and night, 300,000 square feet of roofing was replaced ahead of schedule. “That project had to be completed within 90 and 120 days,” says Baird proudly. “We were one of the first to be down there, with the hurricane relief workers.”

Another unique work that truly shows IRC’s capabilities is the historic Indianapolis Union Station. Located in the city’s Wholesale District, the structure was the first in the world to be designated a Union Station in 1848. Over the years, the three-story building, with its massive Romanesque brick arches, was converted into office space. A striking structure made from brownstone, brick, and granite, it required not only a new roof, but one matching its existing aesthetics. This saw IRC apply a durable, leak-free custom-color roof, matching the way the original looked all those years before.

Safe and sound

Over its many years in business, one of the things that IRC has meticulously and finely honed is its safety protocols. Under the guidance of safety team members Rich Allen and Zabdiel Ramirez, IRC has a reputation for being one of the safest roofing contractors in America. Allen and Ramirez regularly visit job sites, perform inspections, and ensure workers, clients, and the public are protected.

Every year, the company hosts a two-week safety conference, and all field employees undergo comprehensive training and are certified in Occupational Safety and Health Administration OSHA-30, along with forklift, CPR, and other training.

“We make sure we are proactive in safety, and not reactive,” says Baird. “We want everybody to have all the knowledge and capability to use when they are on the roof, and make sure everybody gets home safe at night. That’s our main priority.”

The next chapter

Continuing to uphold the values of founder Melvin Stumler, Insulated Roofing Contractors is looking to the future with anticipation. Revamping the company logo for its 50th anniversary, IRC is giving out t-shirts and other branded merchandise. On May 23, the company will host a party for employees, friends, families, and vendors, celebrating the milestone with music, food, and giveaways.

“I see more crews in our future, and hopefully expansion,” says Baird. “We have this location here in New Albany, Indiana, but I see us growing as a company. I believe we will have future locations in other cities so we can service people quicker. We want to expand our territory, get out to where we are not, and try to get into more territories.”