Wall-tech Companies of Deforest, Wisconsin, was recently contacted by a general contractor who needed help on a construction project involving a three-story, 112,000-square-foot, public charter school going up in Beloit, Wisconsin. Work was behind schedule, and the contractor hoped Wall-tech could speed up the pace of construction.

“They had a very tight completion deadline. This was in the middle of COVID, and there was a shortage of manpower. They needed to enclose the building, and they didn’t think prefabrication was an option because of the complexity of the exterior building,” recalls Wall-tech Chief Executive Officer and Owner Pete Braun.

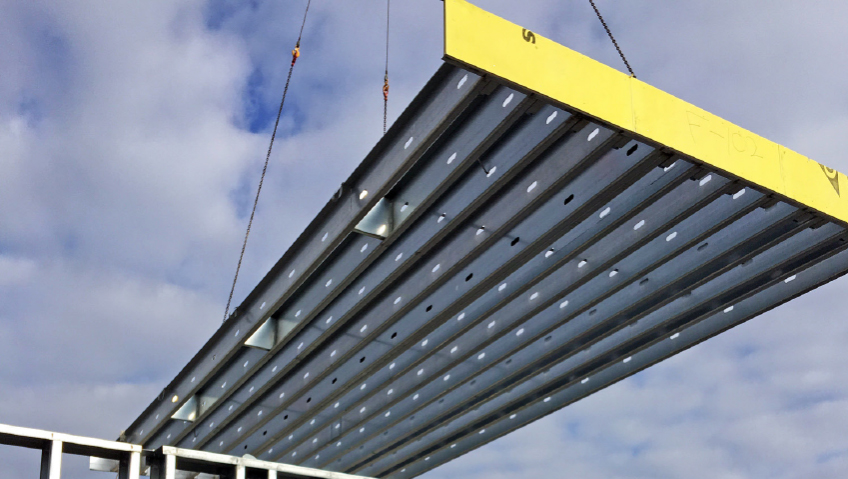

Wall-tech, which engineers, prefabricates, and installs cold-formed steel (CFS) construction framing solutions, took the assignment. At the company’s factory, staff manufactured and assembled 150 CFS wall panels which were then delivered and erected at the job site.

The speedy intervention allowed the client to begin interior work on the school weeks ahead of schedule. “It was a great project for everybody, and they were able to turn the building over on time,” states Braun proudly.

Wall-tech offers both traditional and prefabricated steel framing. Traditional construction entails “sending out an army of people onto the job site and building everything onsite. That’s one part of our business, limited to southern Wisconsin. We have 100 to 150 people that work in that part of it,” he says.

The prefabrication division puts steel frames together at the company’s facility then transports them to construction sites in trailers. Wall-tech installs some premade frames, while at other times, outside firms are hired for this task.

“We contract some work out,” says Braun. “We also work with install partners. When we look at the prefabricated work that we do, we have traveling crews—a group of construction people that will go out and hit different projects in different locations. We’re always looking to team up with other install partners. That might be a general contractor or a carpentry contractor. Someone experienced.”

In addition to CFS framing, the company offers an array of services including wood blocking, structural engineering, drywall and finish taping, continuous insulation, and air/vapor barrier work. The company performs “almost any vertical construction—commercial, residential, industrial. We can do all that,” states Braun.

He cites numerous advantages to CFS framing; unlike wood framing, steel frames are not vulnerable to termites or fire. Steel is stronger than wood and does not rot or shrink over time as wood frames can. While wood-framed buildings can be three to four stories tall, the sturdier and non-combustible nature of CFS framing allows for considerably taller buildings.

Prefabrication, meanwhile, offers additional benefits. For a start, this type of framing can be done with fewer workers. “On traditional building projects, you might have thirty people onsite framing everything. When we’re utilizing prefabrication, once the product gets to the job site you might only need six to seven people,” Braun notes.

Perhaps most importantly, prefabricated CFS framing can be put up fast, compared to traditional framing. “A job that would take eight weeks, we can do in less than two weeks,” he says. “Once we hit [a jobsite], we hit it fast; we hit it hard. We’re in and out fairly quick.”

Sustainability is another benefit of working with cold-formed steel. When CFS steel is used, less concrete is required for framing projects. On top of this, Wall-tech primarily works with recycled steel.

“We’re buying some of the same sheet metal that car [manufacturers] are putting in. We’re no different than GM or Ford. They’re buying recycled steel as well,” Braun says.

Sustainability benefits accrue if a client goes the prefabricated route. As this style of framing can be handled by a small crew, there are fewer vehicles and less equipment onsite. “With prefabrication, you cut down on the environmental impact in the community, with noise pollution and congestion.”

The company works with developers, general contractors, and other clients. In an ideal scenario, a client will get Wall-tech involved during the “conceptual planning stages [of a project] to make sure they have a cost-effective solution,” he continues.

Joining a project at the start makes it easier for Wall-tech to develop design plans which it creates with the help of AutoCAD (computer-aided design) and other software programs. Early involvement also allows it to envision problems that might arise and come up with solutions.

In addition to general contractors, the company works with the various trades involved in a project. Foundations need to be laid and other tasks performed before framing can be erected, so collaboration with skilled trades’ workers is vital.

From its head office in Deforest and presence in Iowa and Milwaukee, Wisconsin, Wall-tech finds that most of its clients are based in the Midwest; however, the company will go “coast to coast,” to complete projects, according to Braun.

One such project that the firm recently finished was a four-story assisted living facility in Berkeley, California. That particular assignment involved “a lot of structural steel, prefabricated wall systems. We shipped that out and hired an install partner to help us. We partnered with a local workforce,” recalls Braun.

Wall-tech’s work is getting noticed. A few years ago, it was involved in a big project for the University of Wisconsin (Madison) Mead Witter School of Music. The facility was 57,000 square feet and boasted a unique design and very precise acoustical requirements.

For this project, the company provided CFS framing, plastering, finishing, drywall, and steel stud soffit framing, among other services. The music school was completed in 2019, and Wall-tech received a BUILD Wisconsin Award from the Associated General Contractors (AGC) of Wisconsin for its work on the finishes of this project.

Ironically, when the company was founded in 1984, cold-formed steel framing was not one of the services it offered. Founder Connie Doering and a small team specialized in exterior insulation and finish systems (EIFS) work with synthetic stucco.

“It’s interesting. Now, we barely do any of that,” says Braun, who laughs then adds, “Let me rephrase: ‘We don’t do any of that now.’”

Braun was brought into the company in 1998 to launch a drywall division. The Wall-tech workforce grew as did the firm’s roster of services which expanded to include framing and finishing, as well as drywall. After the last recession, company leaders held a series of planning sessions to determine its future and decided to emphasize prefabricated CFS framing. Along the way, Braun bought out the founder and other partners and became company owner and CEO.

Today, the volume of work at Wall-tech is evenly split between prefabricated framing and traditional construction, says Braun. This split is even more impressive given that only thirty percent of the company’s workforce is involved in prefabrication work.

Like every North American business, it had to cope with the recent COVID crisis. The company was deemed an essential service so it could stay open, and management took steps to keep its workers safe.

“One of the benefits of prefabrication is that we work in a controlled environment. We’re not working with rain, wind, and snow. We made sure our team were masked and sanitized [their hands] a lot. We have a lot of space in our facility, so there was social distancing. When we do installs, we also took precautions,” states Braun.

The virus did cause some projects to be cancelled, which forced Wall-tech to lay off a small number of employees, primarily on the traditional construction side.

Despite this experience, Braun remains committed to helping others less fortunate and has organized a non-profit group called Contractors Housing America, which seeks to improve living conditions for homeless people.

“We want to get a united front of contractors to provide financial support for existing homeless shelters in existing communities. We’re not building the homeless shelters. We’re providing a fundraising platform to help support existing homeless shelters,” he says. Anyone interested in this initiative—which is scheduled to be rolled out shortly—can go to ContractorsHousingAmerica.org for more information.

He is also determined to spread the word about prefabricated framing solutions. “I think our biggest challenge is educating our customers on what we can do to help them build their buildings faster and better. People have been in this business for a long time, and they’re used to doing it in a certain way. Sometimes it’s hard to break outside of that mold and look at doing something different.”

“We’re going to continue to do more and more prefabrication [and] get better at what we do,” states Braun. “It’s not like we’re going to increase in size by tenfold or anything. [Our growth will be] slow and steady.”

He returns to the notion of customer education and raising awareness about the services Wall-tech offers. “We’re not doing something massively different, just a little different. But even with just a little different, you can get massive increases in efficiency on your job site.”