Thinking about the term hybrid crossover naturally invites one into an imaginary maze of biological processes and even modern cars. However, considered within the context of this retrofit mechanical contractor’s operations, the concept takes on fresh and exciting new significance…

~

Bird Mechanical Ltd. blends the personal attention that comes with a small family business with big-business capabilities and equipment, not only offering diverse services but also emergency support. Rather than being the biggest, this crew focuses on being the best in turnkey mechanical piping, installation, and maintenance contracting. While much of America and Canada are cashing in on strong economies and a financial upturn, the challenge of navigating the modern workforce market has many local operations in a quandary.

The millennial generation is bringing about noteworthy transformations in company cultures around the world. There is no more ‘business as usual’ when this modern wave of change-makers meet their wise and experienced elders.

With its focus firmly on the industrial, commercial, and institutional markets, Bird Mechanical Ltd. has welcomed this powerful change with creativity and ingenuity, integrating its vastly different generational approaches and knowledge bases with its innovative market approach, and its clients are benefitting in big ways.

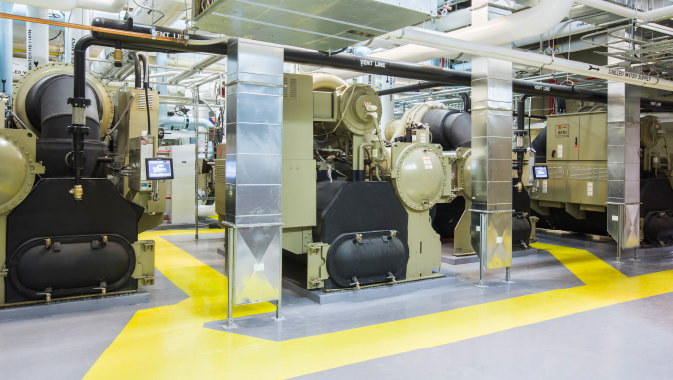

The company is famed for its well-equipped mechanical capacity and supports, upgrades, and expands mission-critical facilities like data centers, hospitals, municipal and government amenities. These facilities typically remain operational during updates, and clients’ day-to-day business can continue with minimal interference. Due to the high levels of responsibility in its work, the company has honed its strength in being the prime contractor on all its heavy mechanical jobs. This means direct contact with project owners ninety percent of the time while subcontracting only a minimal amount of the trade work.

The company is based in Toronto, Ontario, and most of its clients are in the vicinity, but there are also projects running in Barrie, Midland, Hamilton, and all the way east to Kingston, Ontario. Bird Mechanical Ltd. rarely works beyond these geographic areas, but of course, when unique projects do come up further afield, the company is always happy to consider taking on new contracts where it can make a meaningful difference.

The company’s scope is remarkably wide and includes re-siding buildings, reroofing, re-paving parking lots, doing heavy civil excavation work and the like. “We do everything from heating, air conditioning, and emergency systems, like backup generators, fuel systems, rooftop units, chillers, equipment maintenance, and emergency support. These are all part of our normal everyday service offering,” says the company’s Chief Executive Officer Brandon Bird, who took some time out to tell us more about this nimble family business.

The company believes in doing most of its work in-house and has many qualified tradesmen ready to take on even the most challenging projects. These include plumbers, welders, steam-fitters, refrigeration mechanics, and installations staff.

As its construction division sees to projects ranging between $100,000 up to $20,000,000, its 40,000-square-foot fabrication division supports every aspect of its operations, taking care of pre-manufacturing piping system, and preparing everything necessary to facilitate easy on-site installations. Bird Mechanical Ltd.’s service divisions manage the mechanical systems on customers’ plants for both preventative maintenance and emergency situations.

What is now a mid-range company with the capabilities and equipment of a big contractor, started out as a much smaller residential and light commercial plumbing outfit founded by Brandon’s grandfather Jack Bird in 1971. Back then, the company’s focus was mainly on residential work. Brandon’s father, Brian Bird, joined the company in the mid-1970s, beginning as an apprentice plumber and taking over the company during the big recession of 1991. It was ‘sink or swim’ time for Brian, who quickly moved the company towards bigger, more challenging business.

Slowly and with much diligence on its team’s part, its focus on industrial, commercial, and institutional markets started paying off. Brandon started working with his dad in 2002 when he was still at school. His weekends and summer months were spent learning the ropes. The project then entailed a large chiller upgrade at the Hospital for Sick Children in Toronto, Ontario, a $7.7 million project that brought much attention with it.

“Everybody was looking at us, like, ‘What is a company like that doing with a project this big?’ So I was down there all the time on weekends, working with my father and the team, helping with the installation, moving material around, and making sure things were ready to go,” says Brandon. Years later, after training in film, he came back to help set up the new piping prefabrication facility, and after six months, he was in love with the place all over again.

“I walked into my father’s office and said, ‘Okay, sign me up, and I’ll do the plumbing apprenticeship, and I’ll be the third generation of plumbers in this family.’ To this day, I haven’t forgotten the smile on his face when I walked in and said that,” Brandon says. He took over the reins as the chief executive officer in 2016 when his father stepped down after forty years in the business.

Brandon ascribes the company’s success partially to the fact that it has evolved alongside its market. Each project is an invitation to grow and improve, and the company has not been shy of reinvesting in infrastructure and its people.

A notable point that has become apparent over the past three years is the increased focus on the technical capabilities of companies when bidding for contracts. Clients are increasingly making this an important factor in conjunction with price and methods application. Staff résumés and previous experience are also becoming significant components of the proposal process. The company has recently been awarded a number of contracts based on its technical expertise and sterling track record, and this is a rather large feather in its cap considering that it always puts quality before price.

Quality is an indispensable factor considering the nature of its work. Keeping mission-critical facilities running during large upgrades is not for the faint of heart and comes with a host of unique challenges, especially in older buildings where sufficient access to operations centers can prove troublesome at times. Part of the company’s trades’ apprenticeship focusses on dealing with relevant challenges, in this way equipping all its team members to appropriately deal with whatever mechanical hurdles they may encounter in the field.

Of course, communication plays a pivotal role in keeping the right systems going at the right times to minimize interruptions as far as possible. Teamwork is also of the essence, and project managers and coordinators work directly with field staff during the construction phases. “Our project managers are more involved than usual. They have a good understanding of the mechanical systems and the overall construction process because we quite often act as a general contractor,” says Brandon.

For an operation this size to operate smoothly, having well-rounded, knowledgeable staff is imperative. “Having people with solid background and depth of knowledge makes it a lot easier for clients. With us, they’re getting the people with technical skills at the table in stakeholder meetings, so they can consult with our project managers and foremen who guide them through the process,” says Brandon. This ensures a much more streamlined project as there are no middle agents offering questionable advice on big-ticket decisions.

The value of this approach could especially be seen in one of its biggest general contracting and management deals to date. The William Osler Health System’s Etobicoke General Hospital Early Works Project started in September 2015 with a contract value of $10,389,868. The retrofit project involved extensive improvements to the institution’s heating and cooling systems in preparation for its massive expansion. The company did 105 metres of underground directional boring for twelve-inch, high-density, polyethylene drainage piping, installed six hundred feet of eight-inch domestic stainless-steel water line for the building’s new patient tower, and much more.

Throughout the project, the company had to orchestrate meticulous shutdown schedules to mitigate the impact on hospital operations. “We did massive parking lot excavations to tie in the new electrical services, the new plumbing services, and everything, just to ensure that the new hospital was all ready to upgrade,” says Brandon. The project was completed successfully in September 2016 with a final cost of around $10,886,584 and many satisfied smiles.

Behind every successful company is a hardworking team of experts leading the way, and Bird Mechanical Ltd. believes in setting people up for success. It only hires the best and is always investing in technologies and training to keep the team of eighty ahead of market trends. Management supports staff in reaching their career goals and allows people to grow and flourish.

At twenty-nine, Brandon is one of the youngest people in the company but is cautiously optimistic about the future and encourages the younger generation to consider careers in skilled trades. “There’s definitely going to be a big demand out there in the future, especially as the baby-boomers are starting to retire now. We need a new, energetic, and amazing workforce to groom and transfer knowledge and information to,” he says.

When blending very different generations in one company, his advice is to get as much out of mentorship as possible and to apply what you learn in today’s market in a relevant way for the greater good of the business. It takes time to get known for good work in any industry. While he has introduced a lot of new technology and modern equipment to the operation, the company still benefits from the value of reinvestment that his father instilled in him, and Brandon appreciates being able to pick his dad’s brain at times. As a young CEO, he also has staff who are much older than he is, but his multi-generational team listens to and learns from each other continuously.

The company’s goals are clear. It aims to continue diversifying and to become the best in the mechanical piping trade. The redevelopment and building of its service division are now gaining traction, and the company offers construction clients incredible added value in terms of full round-the-clock emergency support that comes with boom trucks, support equipment, backup staff, and resources.

Throughout our conversation, it was very evident that Bird Mechanical Ltd.’s spirit of family and generosity reaches far beyond its own front door. It is no small wonder then that its CEO loves this company and its team so much. “Here, we want to come to work in the morning, and that’s a great feeling.”