From wireless communications to electric transmission and distribution, engineered steel utility structures are everywhere. For decades, Sabre Industries, Inc. has been the innovative manufacturer behind a range of quality, advanced steel utility construction.

~

Sabre was created in the 1970s in Sioux City, Iowa, and has grown considerably over the years. The company started as a high frequency antenna manufacturer and evolved into a structural steel manufacturer in the 1990s. Today, Sabre Industries has grown to a staff of over two thousand, including structural designers, welders, fitters, drafters, administrative employees and other personnel.

Sabre Industries has five manufacturing facilities including facilities in Texas, Ohio, Louisiana and Iowa with over a million square feet of manufacturing space, enabling the company to create steel utility structures of any size, for clients across the United States, Canada and internationally. Clients include investor-owned utilities, government, wireless carriers, construction companies and developers. Sabre has the trained staff, modern equipment and manufacturing capabilities to produce high quality steel utility and wireless structures and prides itself on meeting client deadlines. It has a total annual manufacturing capacity of about 400 million pounds of steel structures from its facilities and performs a range of capabilities in-house.

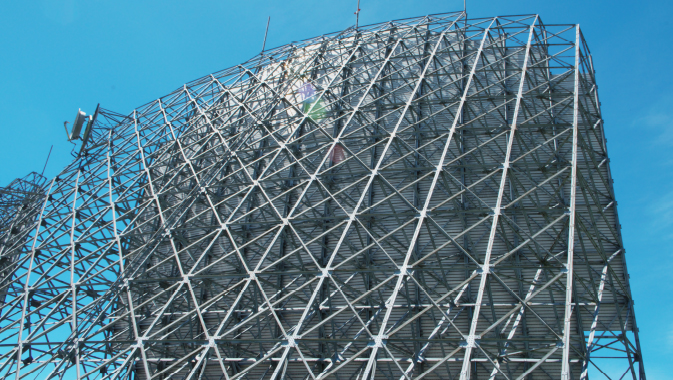

With the wide variety of products offered from telecommunication to transmission, production of various sizes and lengths are accommodated to meet each customer’s needs. The telecommunication structures include self-support, guyed towers, monopoles, concealment structures and small cell products. With its in-house engineers, the company is able to modify existing self-supporting towers and monopoles to upgrade the structure to support the communication demands.

Small Cell Products are in high demand to support the communication in high traffic areas, such as football stadiums and major municipalities. With transmission production, Sabre can manufacture structures of many sizes to support the electric transmission and distribution demands and to withstand the elements of weather conditions. The company’s engineered steel utility products are the result of quality design and precision engineering using customized integrated software programs to ensure the most cost-effective and optimized structure design.

Responding to industry demands for tubular structures, Sabre sought to enter the market as a manufacturer rather than as a reseller, which initiated its tubular structure division. Its precision-designed and engineered solutions replace antiquated wooden poles with quality, long-lasting steel for transmission, substations and other purposes. The company is now responsible for about thirty-five percent of the market. The company provides transmission and distribution poles including specialty structures and has completed projects in every size, from a single pole to lines that are hundreds of miles long. Additionally, Sabre works with clients for their foundation needs. Sabre is one of the leading manufacturers of shelters and cabinets.

Its Sabre Galvanizing Services facility in Alvarado, Texas is home to one of the largest, technologically-advanced, hot-dip galvanizers in North America. As a result, clients benefit from steel poles that are corrosion-resistant and virtually maintenance-free.

The environmentally-responsible company is a member of the Green Suppliers Network and boasts its own testing station, adding to its complement of design, manufacturing and finishing services.

Since the early 2000s, Sabre Industries has garnered much new business through both the quality of its products and manufacturing capabilities and processes and its value-added processes. These processes include hot-dip galvanizing and the benefit of R&D through full-scale testing on tubular steel structures as well as wooden and concrete poles. The testing station provides both destructive and non-destructive testing of structures and poles up to 235 feet high and is used for a range of transmission and distribution poles, standard class poles, substation structures and substation buildings.

While still holding a lot of traditional face-to-face meetings and undertaking business development, much of the company’s growth in recent years has been the result of word-of-mouth praise from existing customers in many sectors.

“It’s not only the process and on-time delivery of the structures but our engineering services, project management and way contracts are administered,” says Andres Franzese, Senior Vice President of Sales and Marketing. “There is a lot to it other than delivering steel.”

Despite the rise of smartphones and high-speed internet, much of its growth is not in the cellular market, but the utility market. Across the United States, a great deal of the existing infrastructure for power is old, fragile and obsolete.

As utilities like electricity continue to invest in their infrastructure, Sabre Industries is experiencing substantial activity and investment in that area. The utilities sector is also undergoing a shift from coal-based operations towards gas-fired energy plants and an increase in renewable sources of power such as wind and solar, with additional lines being added for improved reliability.

“We are seeing significant growth,” says Franzese of improvements to many investor-owned utilities across the U.S.

In some cases, Sabre’s work comes from dire need. Texas and Puerto Rico, badly damaged by Hurricane Harvey and Maria last September, will require extensive repairs and rebuilding of not only homes and other buildings, but also reconstruction of its electrical grid, essential to get the territories operational again.

“The next eighteen months will see the reconstruction of Puerto Rico and southern Texas.” And the demand is growing for better mobile technology such as 5G (fifth generation wireless systems) that enables greater densities of mobile broadband users and drastically faster data rates. As this happens, Sabre Industries will play a pivotal role.

Sabre is certified by the Canadian Welding Bureau and the American Institute of Steel Construction (AISC). All welding procedures are followed by the AWS standards. “Each welder is certified per the AWS codes and Sabre staffs Certified Weld Inspectors to inspect all our products. Those are the types of thing that make a lot of noise in our industry, certifications over awards,” comments Franzese of the company.

“Sabre industries will continue to grow. The entire executive team is very driven towards conquering more and more of the market. Right now, our plans are to continue on the growth path that we’ve been in.”