The concrete building sector is going through a revolutionary period characterized by a number of transformations, including groundbreaking inventions and a resolute dedication to sustainability. Technology continues to change the industry, helping it move from more conventional methods to processes that increase productivity, lower worker injuries, and protect the environment. As a result of the focus on inclusive and efficient construction technology and environmental stewardship, this transition represents a significant shift in the industry’s perspective on worker safety and sustainability as the industry embraces a future beyond simple productivity.

According to the International Society for Concrete Pavements, the concrete and cement sectors are steadfastly moving toward sustainability, with an emphasis on environmental product declarations (EPDs) and openness of processes. Customers are looking for materials that minimize embodied carbon without sacrificing strength and durability, which is driving demand for low-carbon concrete.

With the retirement of coal-fired power stations, the fly ash market is changing. Fly ash is an essential ingredient in sustainable concrete mixtures. To guarantee its continuous use in the manufacturing of concrete, businesses are investigating beneficiation technologies for processing stored fly ash. Furthermore, ground-granulated blast furnace slag is becoming more popular because of its advantages in terms of sustainability and performance, indicating future expansion for this industry.

Eco-friendly materials and sustainable construction methods are the main topics of investigation for green construction technology, with ecologically conscious building practices that include the use of cutting-edge insulating materials, solar-integrated construction, and creative waste reduction strategies, writes Indovance. These technologies seek to reduce the environmental impact of building projects as environmental awareness gains prominence, with smart construction concrete, shape-shifting materials—materials that, when bent, revert to their former shape—and cutting-edge technology designed to improve construction methods’ functionality, sustainability, and durability.

The industry is definitely seeing a movement toward more sustainable methods, such as using products with lower environmental impact, according to Design Cost Data. Over the course of their lifetime, buildings are being designed with lower energy usage and operating expenses in mind. Although adopting this practice can be challenging as sustainability typically translates into higher costs, technological developments are taking aim at lowering the cost of more sustainable materials.

Novel materials like bio-cement and self-healing concrete have been made possible by ongoing research and development. These materials seek to increase a building’s lifespan and efficiency while reducing their negative effects on the environment. There are positive indications that many of these materials may find their way into the industry sooner rather than later, even though research and testing on them is still ongoing.

The idea of NZEBs (Net Zero Energy Buildings) is also gaining traction, according to Design Cost Data, thanks to government initiatives and environmental concerns. By producing their own energy, these structures reduce their reliance on outside power sources and their carbon footprints, and can be achieved by installing solar panels or by utilizing more ecologically friendly materials like ICFs (Insulated Concrete Forms) and heat pumps.

Because of their effectiveness and sustainability, eco-friendly materials such as cross-laminated timber are becoming more and more popular. Prefabricated materials are important for the environment since they save time and minimize waste on building sites, and while this technology is not a new construction innovation for 2024, experts still predict it will become more common.

Along with a fresh focus on greener concrete, there are a host of other technological transformations taking place. With technology constantly evolving, its use within the construction industry continues to proliferate. However you feel about AI, it is being used by the industry more and more to improve concrete mixes and advance performance-based design, says the International Society for Concrete Pavements. Producers can minimize carbon emissions and customize mixtures to individual project requirements by utilizing AI technologies. The move to performance-based mixes has the potential to completely transform the building industry by providing project-specific, sustainable solutions.

By automating several activities and offering data-driven insights, AI is transforming project management, according to Indovance. AI algorithms examine enormous volumes of data to find possible dangers, improve project timetables, and suggest resource allocations, resulting in better decision-making, more precise forecasting, and increased project efficiency. According to Deloitte, construction projects will see operational cost savings of between 10 and 15 percent thanks to AI and data analytics.

Construction has only been improved by technology, adds Indovance, with digitization making processes more streamlined, accurate, and efficient. Technologies used in construction are diverse and include Building Information Modeling (BIM) for accurate project visualization and generative AI for resource allocation and design optimization.

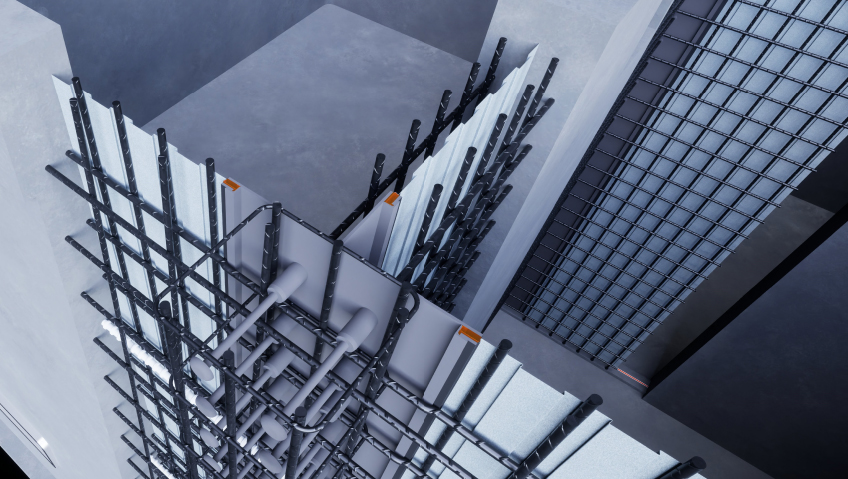

BIM allows architects, engineers, and construction specialists to work together by generating a digital depiction of the whole building process, a technology that facilitates effective communication between stakeholders, reduces errors, improves project visibility, and helps uncover any clashes. Automation and robotics are being incorporated into construction operations to improve accuracy and efficiency, making it simpler to perform labour-intensive tasks like welding, excavation, and bricklaying. Additionally, automation speeds up time-consuming and repetitive tasks, resulting in shorter project schedules overall.

3D printing technology is also helping to create unique structures, utilizing techniques that cut expenses, shorten construction schedules, and minimize wasteful material use. 3D printing is changing conventional construction techniques and opening up new options for sustainability and design, from printing concrete structures to creating personalized architectural features.

Augmented Reality (AR) projects digital data onto the real world in order to provide on-site support, while Virtual Reality (VR) is utilized for training simulations, virtual walkthroughs, and immersive design visualization. These technologies help project teams collaborate better, communicate more effectively, and make fewer mistakes.

Drones have also quickly integrated themselves into building projects, even though robots are still not commonly recognized, says Design Cost Data. Their main functions are site surveying, inspections, and the creation of 3D models, which support the ground-level study that also takes place. Unmatched in efficiency, these UAVs (unmanned aerial vehicles) make it possible to evaluate project site progress and spot possible problems more quickly.

The use of IoT (the Internet of Things) improves decision-making and operational efficiency in building projects by enabling real-time data analysis, predictive maintenance, and exact resource allocation, maximizing project results. Mobile access to remote worksites allows for real-time inspections, on-site accountability, and virtual collaboration, three uses for mobile applications that are growing in popularity. Even from remote places, these platforms allow project stakeholders to communicate easily with one another.

And, according to Indovance, the application of blockchain technology in the AEC (architecture, engineering, and construction) space can enhance accountability and transparency in building projects, supporting safe contract management, material source tracking, and the preservation of an immutable record of project transactions.

When it comes to labour shortages, creative answers are needed to address this ongoing problem in the construction sector, according to Design Cost Data. Leading industry players are increasingly using automation and artificial intelligence tools to streamline operations, especially when it comes to labour-intensive or repetitive jobs. To close this gap, there needs to be a renewed emphasis on employee retention together with effective recruitment techniques.

Enhanced worker safety is also a priority. Technological innovations such as wearables, virtual reality, and artificial intelligence (AI) are transforming safety protocols. By providing immersive training experiences, real-time monitoring, and predictive hazard analysis, these advances dramatically lower workplace accidents. Construction equipment is also becoming safer in addition to personal protective equipment, with the advancement of safety technology remaining at the forefront thanks to more sophisticated sensors, improved ROPS technology, and improved visibility.

In short, there is no denying technology’s transformational power, particularly in the concrete industry. Cost-effectiveness is only one aspect of the larger change being seen in which technology is becoming the mainstay of environmentally friendly behaviour. These developments promise economic benefits and usher in a new era of environmental responsibility with an emphasis on greener construction and climate resilience. As a result of the convergence of these technologies, this year will be crucial in laying the groundwork for a more economical, ecologically friendly, and productive future in the building sector.

The construction sector is always evolving as a result of societal needs and technological breakthroughs. It’s not only about development when it comes to staying ahead of emerging trends; in this ever-changing sector, it’s essential for survival and success. By using all available technology, businesses are actively seeking to reduce lifecycle emissions from their projects, an essential step in creating a future that is more ecologically friendly.