Whether it’s restaurants, sports complexes, libraries, or residences, Quebec-based Art Massif has been designing, producing, and installing glulam wood structures for a variety of structures since 2010. Driven by excellence and a desire to design and produce unique, high-quality, glulam timber constructions that push the boundaries of what’s deemed possible, Art Massif infuses projects with attractive designs through unwavering focus on optimization and ongoing improvement.

With wood obtained from Quebec’s sustainably managed forests and an SFI certification, Art Massif ensures clients are supporting ethical and responsible forestry practices while also helping to preserve biodiversity and natural ecosystems.

“Art Massif was founded by a passionate woodworker and craftsman who really put a lot of attention on details and designs,” says Dave Savard, Sales and Marketing Director. “It started fairly small with a project that was requested by one of his friends, and it had a pretty big impact, which generated more word-of-mouth requests, more demand, and more clients who wanted to have Art Massif as part of their life.”

What began as a very small operation in a garage grew quickly in a short period of time, along with the size and scope of the buildings and the need to use glulam timber.

“Pretty early in the process, innovation was one of the drivers of the company,” says Tristan Gagnon, General Manager. “People were coming to Art Massif and asking for specific things or projects and the mentality, the philosophy we still have today, still always start with ‘Yes.’ We don’t say no to pretty much any project, and we find solutions to deliver what the customer has in mind or what he dreams for the building.”

The company has continued to expand, moving from residential in the early days to small commercial buildings to larger commercial buildings, and now to very large, innovative structures. This has led to the company rebranding and refreshing its logo and corporate identity to reach a target clientele that has evolved and shifted over the years.

“We started with small residential projects and now we’re into large, commercial buildings and institutional buildings, with the same vision and philosophy of innovation and design that we’ve created since the beginning,” explains Savard. “Our target market has also expanded; we started locally and now we’re collaborating on projects through North America.”

The rebranding was also a way to include Art Massif employees and help the company culture evolve at the same time. “The brand agency we’ve worked with has included the employees from the start in the first consultation and also at the launch,” Savard says. “The production team and the sales and engineering office were invited to an internal launch event where we explained why we were doing this and why this logo was selected. That is really important being a small business—the employees are at the forefront of our success.”

The differentiator at Art Massif is in accompanying clients from the beginning of their project, he adds. “We like when we can be included in the discussion at the really early stage and create a true partnership with our client and their team. We want to be involved at the beginning because we can help our client to imagine an even better project and optimize their structure with Art Massif’s capacity.”

With a large team of engineers on the sales, project management, and engineering teams, who are involved every step of the way, the company helps find the best way to execute the client’s vision. “We’re doing more and more design-build to make sure we optimize those structures,” Savard says. “We’re working closely with clients at the conception stage to make it more cost-efficient, but also make it the best design structure we can.”

Art Massif also maintains strong partnerships with installation companies, allowing for optimization and efficiency of installation. “It’s our mission to have a highly efficient way to deliver a structure,” says Gagnon. “We have the installation crew that is working closely with our project manager and shipping department, so the shipping is optimized in the way that the installation crew wants it. We’re looking at the complete process up to the last screw.”

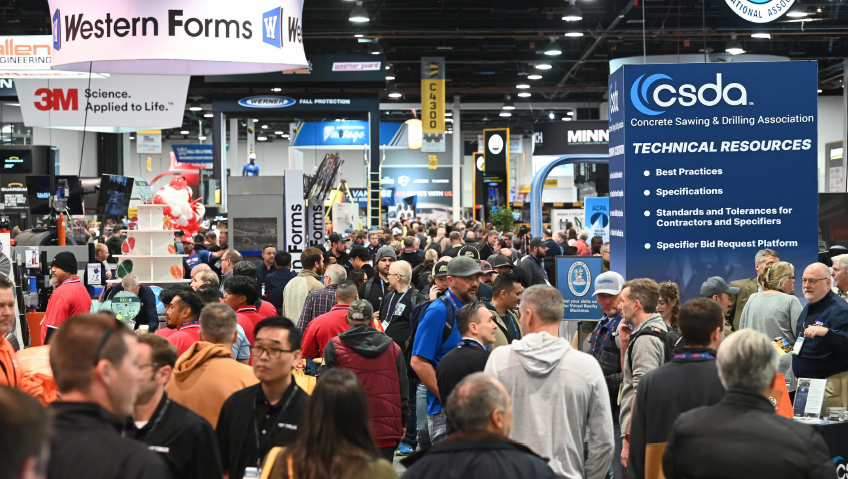

The company’s attention to efficiency and quality has resulted in a strong reputation in the market along with a sound presence at industry trade shows and conferences. Art Massif also has the knowledge to share with architects, as more wish to build with wood but don’t possess the expertise.

United Therapeutics Airplane Hangar in Concord, New Hampshire is a good example of a relationship Art Massif has forged with the builders directly, adds Gagnon.

“We really take the projects and customers’ needs seriously, and we changed our plan to make the project as it needed to be,” he says. “We really have been supporting our customer in having the project they want… We supported them throughout the building of the hangar, which they appreciated.”

That customer satisfaction has helped generate continual leads and more projects moving forward, adds Savard.

Art Massif’s dedication to sustainability has also helped create a loyal customer base, with a production plan that uses all its waste wood to heat the building and a desire to optimize every part of the lumber such that each project is designed in the most efficient way possible.

“We make all of the efforts on efficiency, using a greater portion of the lumber, and reducing waste,” says Gagnon.

The company is also seeing more demand for glulam projects, and specifically the type of refined design Art Massif excels at, which means the team is always trying to find the right investment at the right time to meet this demand. “This requires investment and growth,” Savard says. “It’s a positive challenge, and now we’re investing a lot in new production equipment, we’re expanding the building, and we’re investing in people.”

The management team is doing different things to maintain the company culture and attract the right people, particularly the best engineers and those who specialize in wood structures. “We would like to double the team if we can, to double the projects that we take on, but I feel we have the right culture and the right actions in place to attract those people and build a performing team,” says Gagnon.

Those people are needed to help complete more projects like the aforementioned Concord airplane hangar, which was innovative in many different regards, specifically in the shape of the trusses and structure, which allowed Art Massif to do a 210-foot free span, optimizing the floor layout for airplanes without any supporting columns.

“It was an interesting building for sure,” says Gagnon of the structure, completed for United Therapeutics’ medical transport planes.

The project also had a very low carbon footprint, something that wouldn’t have been possible using other traditional building materials. “It was also done in a really, really fast timeline,” says Gagnon. “We had the complete design process; it was a design-build, so the whole engineering team had a blank page to start from. The building uses all of the technology that we have been investing in for the past few years.”

The project wouldn’t have been possible, he adds, “without our CNC machine and without the building space Art Massif has now. I’m proud to say that our investments are dedicated to serving our clients’ needs,” he says. “The building we’re working in and the kind of structural design and quality beams we can deliver really differentiate us from the others and the complete process in our organization really serves the customer as well as possible.”

The entire company’s commitment to working with clients from beginning to end to create unique, breathtaking buildings helps keep the company on the cutting edge of design and innovation.

Expansion is also an ongoing goal for Art Massif in order to reach as many clients as possible; the team is continuing to expand in Canada and the USA where wood structures are more and more popular.

“We’ve done some pretty cool design projects over the years locally in our backyard, and we’re going to continue to be strong in our market for any kind of wood structure project. For Art Massif, our team gets excited when we contribute to creating an interesting design with curved beams and crazy structures. And we are totally happy to help any client to get a wood structure in their building, no matter the size or design!”

Expanding its market reach also provides a better pool of access to the great projects that Art Massif likes to work on—that its engineers get excited to work on—and where the company can really bring value by doing something different, he adds.

“We want to continue to develop our art and sophistication in the design efficiency of the structure, to build bigger buildings, more sustainable buildings, and always to keep design in mind to really raise the bar,” says Savard. “In every kind of project we do, we like to do it differently: to keep developing the product, to keep pushing the industry, and raising the bar of the wood structure overall.”