DY Concrete Pumps Inc. of Alvarado, Texas and Calgary, Alberta is gearing up for new products, an e-commerce website, and a milestone anniversary. The company acquires pumps and parts made by South Korean firm DY Innovate (DYI) and ships them to Texas. There, welding, manufacturing, electrical, driveline work, and assembly is performed. Completed pumps are sold directly to clients through a widespread network of sales staff across Canada and the United States.

Since we last spoke in October 2023, “The single biggest change at [DY] would probably be us diving heavier into the line pump market. At the last World of Concrete show, we launched a new line pump called the HP-3250,” shares Marketing Director Braden Huggins.

Concrete line pumps feature stationary pumping units mounted on trucks or trailers; they are compact, deliver concrete through a hose, and are commonly used for residential projects such as driveways or pools. The company, which is based near Dallas-Fort Worth, also supplies truck-mounted boom pumps which feature long boom arms that flow huge volumes of concrete for large-scale work involving airports, sidewalks, tunnels, parking lots, dams, high-rises, and the like.

The HP-3250 Line Pump (the initials stand for ‘high pressure’) offers a maximum output of 144 cubic yards per hour and has a unique dual-pressure system. “Typically, these types of machines can only be in high or low pressure, and you have to swap out hydraulic lines [to change pressure]. It’s a long, convoluted process. With this machine, you just switch a lever,” explains Huggins.

The HP-3520 can be used with a chassis from manufacturers such as Western Star, Freightliner, and Mack. DY hopes this line pump will build on the success of its CTY-100 line pump, a popular product with a 14.1-cubic-foot capacity hopper that is mounted on a pickup truck. Recommended for urban settings or compact work environments, the CTY-100 is currently DY’s main concrete line pump.

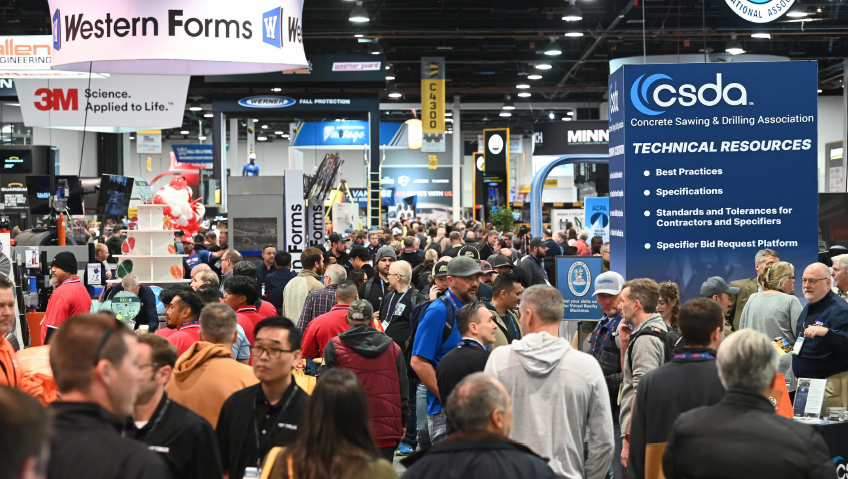

As Huggins notes, the HP-3250 was presented at the January 2024 World of Concrete trade show in Las Vegas, a hugely important industry event. World of Concrete “is the largest concrete-related show in the world, and it’s the only opportunity for us to participate in something where our customer base would go. We don’t have regional shows; we don’t have international shows. This is basically it. It’s the biggest and best, and you almost have to be there,” says North American Sales Manager Mike Morris.

“In a way, it’s an honor [to be an exhibitor at World of Concrete]. They put all the concrete pump manufacturers in the center of the biggest hall. You are the star of the show in a way, as a concrete pump manufacturer. It’s a chance to show what you’ve got and really try to impress people,” adds Huggins.

This is not hyperbole; the World of Concrete website describes the gathering as “the industry’s ONLY annual international tradeshow dedicated to the commercial concrete and masonry construction industries.” This trade show has been going on for over half a century.

In addition to spotlighting new wares, DY enjoys the networking opportunities at World of Concrete, meeting current clients and prospective clients face-to-face. “That’s kind of the fun part of the trade show, too—the networking aspect. You meet these guys and over the years, you see them grow. You get to meet them again and again each year and catch up,” says Huggins.

The DY team is already preparing for the next World of Concrete show, scheduled for early 2025, also in Las Vegas. If all goes to plan, DY will officially unveil its new e-commerce site at this event, following a soft launch this fall.

“We’re very excited about that,” says Huggins. “Honestly, we delayed our launch of e-commerce because we want to do it right, set everything up our way, with our system and with our inventory. It’s going to be a game-changer.”

Long in the making, the new e-commerce site will augment the company’s existing capabilities. It has well-stocked brick and mortar parts and service centers and can deliver parts “for every concrete pump and model available,” within 24 hours. The new e-commerce site, featuring all manner of components, parts, pumps, and ancillary gear, takes this customer-first focus a step further.

“Our customer base can order their parts from a computer screen and have them shipped, as opposed to picking up their phone, calling, and then stopping by on their way home. It’s easier access for our customers [and allows them] to utilize their time better,” explains Morris. DY is eager to “expand our parts and service footprint throughout the country in the near future,” he adds.

As for other new products, DY will soon be introducing the TP-50 and TP-70 trailer pumps. Both are 16’ 2” inches long and 7’ 10” tall. They are trailer-mounted and require a hose for placement of the concrete. The TP-50 offers a rod-side output of 54 cubic yards per hour and piston-side output of 38 cubic yards per hour, while the TP-70 offers rod-side output of 73 cubic yards per hour and piston-side output of 48 cubic yards per hour.

“While the trailer pump market is fairly saturated,” the high-quality TP-50 and TP-70 should offer “a nice entry point for us,” says Huggins.

DY Concrete Pumps marks its tenth anniversary next year, an event it plans to highlight with an open house and celebratory marketing material. “It’s a big deal because, in the market, there’s a lot of uncertainty of any new company in the industry. When companies purchase heavy equipment, there’s a lot of trust required between not just the owner, but the operator and the manufacturer,” he says. “It’s a real partnership between manufacturer and end user.”

Morris says the company’s success is a testament to its leadership. “DY’s motto is ‘concrete pumps built by pumpers, for pumpers.’ We stand behind that in what we do. It all starts at the top here and the expectations of our leadership trickle down… You can buy a concrete pump anywhere, but you cannot buy our people. That’s what you’re getting when you get the DY product: industry-leading backing from industry-leading people.”

The company uses social media to help spread the word about its commitment to service and quality wares, and it is starting to get into more detailed, technical content. Such content might entail, say, a video detailing pump truck features or insights about solving common construction problems.

As for new hires, “You want someone who can be passionate about this stuff. Even though you don’t know what a concrete pump is when you come here, we want you to get excited, not necessarily about the product—maybe you don’t care about construction—but get excited about something, like the relationship with the customer, with your co-workers, or the skills you’re honing,” says Huggins.

Indeed, DY’s corporate culture is built around the idea that “everybody in this company is a salesperson. I don’t care if it’s the welder on the floor; I don’t care if it’s the accountant in the back,” says Morris. He does not mean that all staff members are required to go on sales calls, but that each employee must be mindful of representing the company at all times. The attitude and behavior of any staffer can influence sales down the line, for better or worse.

As DY approaches its tenth year in business, it faces certain political and economic headwinds. This is a U.S. presidential year, so there is uncertainty about future government policies that will affect businesses. On top of this, Chinese-made concrete pumps are making inroads on the North American market, driving down prices.

“There is nobody that manufactures a concrete pump—a boom concrete pump—in the United States, period. We’re all relying on external international markets, whether that be Korea or Turkey—where there’s a manufacturer—or China,” Morris says. However, concrete pumps from China are sometimes constructed with cost savings, not quality, in mind. If budget-conscious contractors show a preference for cheaper pumps, that impacts the revenue of suppliers of higher-end products. For its part, DY doesn’t source any steel from China, Morris notes.

Despite such challenges, he remains an optimist. “With over 300 delivered units, this company is just now getting traction in this market. I see this company in the next five years easily doubling in size,” he says.