CROM has been building and restoring essential water and wastewater infrastructure for municipalities and private clients since 1953. The Gainesville, Florida-based business is a market leader in prestressed concrete tank design and continues to innovate. After featuring CROM in December 2023, Construction in Focus is checking back this month to learn about the company’s latest solution.

CROM has recently unveiled the CROM2 straightwall watertight tank, which was engineered with the same benefits as prestressed concrete tank technology. CROM2 was created with the intent to upgrade from traditional cast-in-place structures. Market demand motivated the team to provide their newest solution.

“The reason for developing CROM2 was to answer a call from our clients,” said Senior Vice President, Alex Ciasca. “We’ve been building circular prestressed tanks for more than 70 years, and throughout the years, our clients have asked, ‘Can you apply this same watertight technology to a square or rectangle tank?’ The call to action wasn’t to replace CROM’s prestressed circular tanks, but to serve a parallel market utilizing decades of proven innovation and methodology. “Until now, the answer had always been no. When clients continued to ask the question, we came together to provide an answer.”

The development of CROM’s most recent product was not without its challenges. The first was “ensuring prior to going to market, that this product lived up to the standards and expectations we established during our 70 years of commitment to quality,” Ciasca said.

Then there was the specific challenge that came with creating a tank with corners—but CROM’s engineering, drafting, and manufacturing teams were well prepared by building on previous innovations.

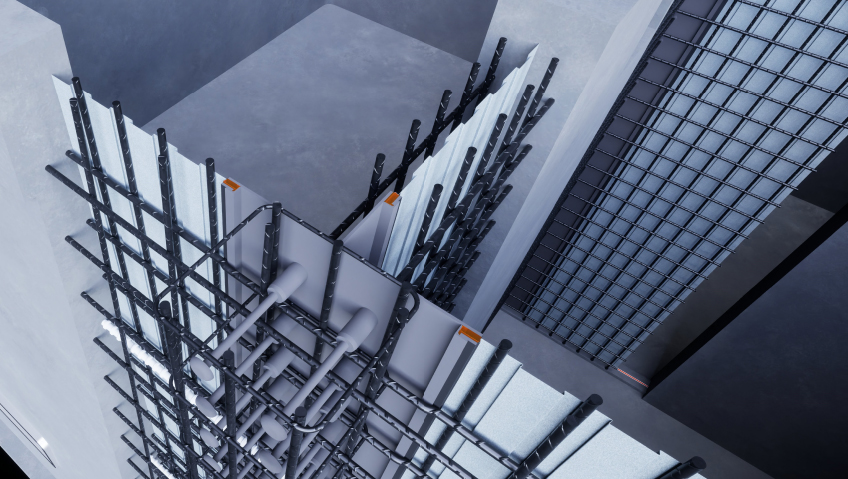

“This is not new technology,” said Region Lead and Business Development Manager, Daniel Haugland. “The technology we’ve put into CROM2 has been around for 71 years. It’s the same composite wall we’ve used in our circular tanks; we just needed to make the corners work. It’s important for people to know the same CROM quality, the same CROM technology—with a few modifications—is what you’re getting with CROM2.”

The benefit of the tank, according to Haugland, is its durability. CROM’s age-old technique of post-tensioning shotcrete with a metal diaphragm and the addition of their newly engineered patented connection details make it possible for CROM to create a compressed straightwall watertight tank.

When compared to existing straightwall offerings, “We enhanced the design,” Haugland said. “The composite wall design is a galvanized steel shell diaphragm encased in high-velocity shotcrete, which provides a watertight barrier should the water ever find a way to migrate into the wall. It is the combination of the positive attributes of both steel and concrete tanks in a single straightwall structure.”

CROM continues to add to its portfolio of water infrastructure solutions. CROM2 marked another component to its full-service offerings, allowing a simplified building process for the client. “Like CROM’s previous innovations, we’re relying upon our in-house design-build resources, so the client experiences zero division of responsibility,” Haugland said.

The company stands behind its products by providing a five-year warranty on all straightwall tanks, an option that isn’t offered for traditional cast-in-place tanks. “Our warranty is one of the defining benefits of CROM2,” Haugland said. “Usually with a cast-in-place structure, the customer receives a one-year warranty.”

“The five-year warranty has no exclusions,” Ciasca followed up. “With CROM2 , we guarantee 100 percent watertightness, and as always with CROM, if there are any issues, there’s only one phone call to make. You don’t get that with any other product out there.”

CROM’s full-service approach is not only meant to give its clients peace of mind but to make it easier for clients in case repairs or upgrades are needed.

There are also notable cost savings with CROM2. “We have a much lower lifecycle cost than some of the other designs,” Haugland explained. “With some designs that have cold joints, you need coatings on day one, which becomes a regular maintenance item every seven to ten years. With ours, it’s just a smooth homogenous shotcrete surface with no cold joints, ensuring a much longer design life.”

CROM2 is an ideal solution for “anyone who needs a long-lasting, low-maintenance straightwall watertight tank or space-saving treatment structure,” Ciasca said. “Anyone who values those items or qualities would be a target customer for us.”

CROM uses its extensive experience and knowledge to fully support clients through restoration services, tank offerings, and other water infrastructure solutions.

“Between our circular tanks, our square and rectangulars, and the wide range of services we provide within the water infrastructure, repair, and construction base, we have a lot of experience we can bring to the table to help our clients,” Ciasca said. “Whether for an owner or an engineer or contractor, CROM will develop unique solutions tailored to their project, utilizing all of the experience we have to offer.”

CROM is a water infrastructure solutions provider in the water, design, restoration, and maintenance space, and this added technology continues to showcase CROM’s versatility and ability to be a resource for its clients and communities. After building on seven decades of experience to develop CROM2 to meet a market need, the team is eager to keep supporting clients far into the future.

“We’re going to continue to innovate as we always have,” Ciasca said. “That’s what CROM does: we continue to meet the call of our clients.”