After profiling Champion Bridge Company in 2021, Construction in Focus is circling back to hear how the company is celebrating its 150th anniversary, find out more about notable projects, and learn what to expect for the future of this long-lived company.

Champion Bridge Company credits its employees for the company’s remarkable longevity. Estimator and Project Manager Noah Dell emphasizes “how appreciative we are of all the employees that we have working here now and all the employees that have participated in our hundred and fifty years. It really does come down to the people that have been here and the people that are here now. We are very grateful for them. That especially starts with my dad [and Champion owner] Randy, who has been here since 1977. Definitely a core figure in the company.”

Champion is ringing in its 150th with a complete rebrand, updating its logo and colors and creating anniversary-specific materials to market and commemorate the momentous occasion, including producing a book to preserve and showcase Champion’s story, complete with photographs. The book will give a snapshot of the company’s history with a focus on the last fifty years. “It should be a nice publication that we’re going to put together,” Dell says.

In September, Champion will host a big open house with a ribbon-cutting ceremony for the community, subcontractors, and suppliers to attend. The anniversary celebrations will culminate at the end of the year with a company dinner where the team will reveal the 150th anniversary book and hand out awards. The goal will be to acknowledge “individuals in the company that are exhibiting core values to a high degree, that are setting the bar for us,” and to encourage the team to maintain those core values “for the next one hundred and fifty years,” says Dell.

After a century and a half in business, Champion has plenty of projects to highlight. One of the most remarkable is the Martinsville Covered Bridge. Built in 1871, the quaint, wooden bridge is still in use today. “They’ve done a good job preserving the history of that bridge,” Dell says. “It’s neat to know that there’s still some bridges standing that are that old.”

Champion completed the Snow-Reed Swing Bridge in 1925 in Fort Lauderdale, Florida. “They’ve also done a great job of preserving that one, and it’s a historic landmark in Florida,” Dell says. “This bridge is actually still operational, where they can actually turn the bridge, pivot the bridge, so boats can go down through the canal and then it can rotate back to allow for traffic.”

After constructing historical landmarks as well as lesser-known bridges for its first century in business, Champion’s focus transitioned to structural steel, primarily supplying contractors throughout Cincinnati, Dayton, and Columbus, Ohio. “We pretty much got out of bridge-building entirely by the 1970s,” Dell says.

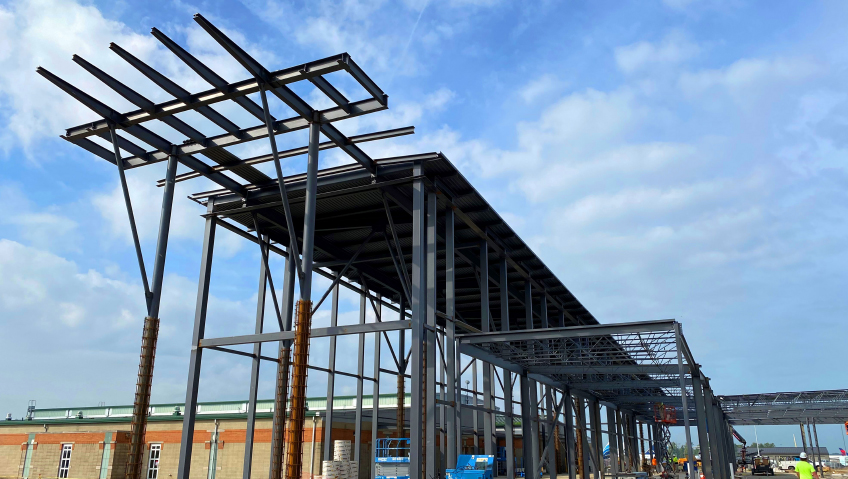

The company has a proud track record of commercial building fabrication over the last fifty years. One noteworthy recent project is the Laurel Oaks school addition with Dugan-Meyers/Megen Joint LLC. The construction required 360 tons of structural steel. Champion’s sixteen-person team was particularly enthusiastic about this project because it took place in their community.

“It’s right here in our hometown,” Dell says. “Community development is a big deal for us so it’s always great to have local projects.” Located “just a couple of miles down the road,” some of the company’s welders have even attended the school. “So to be able to participate in building their school was a fun project to be a part of, and architecturally, [it] is a very unique job that really stands out, is very attractive, and really shows off the craftsmanship that our guys can do today.”

Champion also supplied structural steel for Kinetic Vision’s new, custom-built $11 million facility in Cincinnati, which was inspired by Northwest architecture and combines large expanses of architectural metal panel, porcelain tile, and traditional brick. This was “a large job, unique job, and a very pretty job,” Dell summarizes. “It exhibits the type of stuff we build.”

A large project currently in progress is for the new Mercy Health hospital, which will require over 400 tons of structural steel, and an even bigger project is on the horizon. It “is a job that we are going to be doing this fall and it’s over 900 tons of structural steel [for] a large cardboard recycling plant that’s going in down in Kentucky,” Dell says. “That’s by far the largest contract that the company’s ever done. It’s so neat to get that one booked and will be a fun challenge this summer to get all the work done.”

Champion embraces the latest technology to ensure the best outcome on all the company’s projects, and 3D software is just one of these technologies. “One thing that we definitely are taking advantage of more and more is all of our projects are designed three-dimensionally in 3D software before they ever hit the shop floor,” Dell explains. “Historically we get the design drawings in a 2D format, and then we create the three-dimensional model, and then it goes back to two-dimensional for our shop drawings.”

Now, however, the company is making the 3D model a priority, and, the team is sending the 3D drawings into the field along with the standard 2D renderings to give contractors, subcontractors, and employees “a much quicker and better feel for what it is we’re building than just looking at a two-dimensional piece.”

The impact is noticeable and immediate. “Utilizing that model definitely has advantages,” Dell says. “Just today I was looking at a project that is in process and I was looking through the model and I realized that they had some connection design that I really don’t like, that I would rather go with a different option, and to be able to just quickly glance at the model and note those differences and be able to see it and then talk to detailers about changing it before it goes to fabrication—it is definitely very helpful and it has a big impact on what we do.”

Currently, Champion is in the process of transitioning to fabrication management software. “The goal is to have it completely implemented, released in the shop and throughout the business operations, this year,” says Dell. “That’s going to enable us to have a lot more real-time production information, so we can keep track of schedules and keep track of material and do a better job of recording the time it takes, so our estimating becomes more accurate and then our schedules become more accurate. And that software also really ties into and works well with three-dimensional design software that we use.”

After a century and a half in operation, the team is eager to keep the business moving forward. One major goal is to expand the company’s workspace. “We’ve been in the current facility since 1893 when we built it,” Dell says. “We’ve tripled production over the last five years, and I feel like we’ve really kind of hit that ceiling with the current facility as it is. We just don’t have more room to get more and more steel out the door.”

The team is currently considering “the quickest, most affordable way to expand our capacity,” with the goal to “keep growing and keep serving our customers.” With such a long and storied history to build upon, the company certainly has a lot to look forward to, including huge potential for ongoing growth.